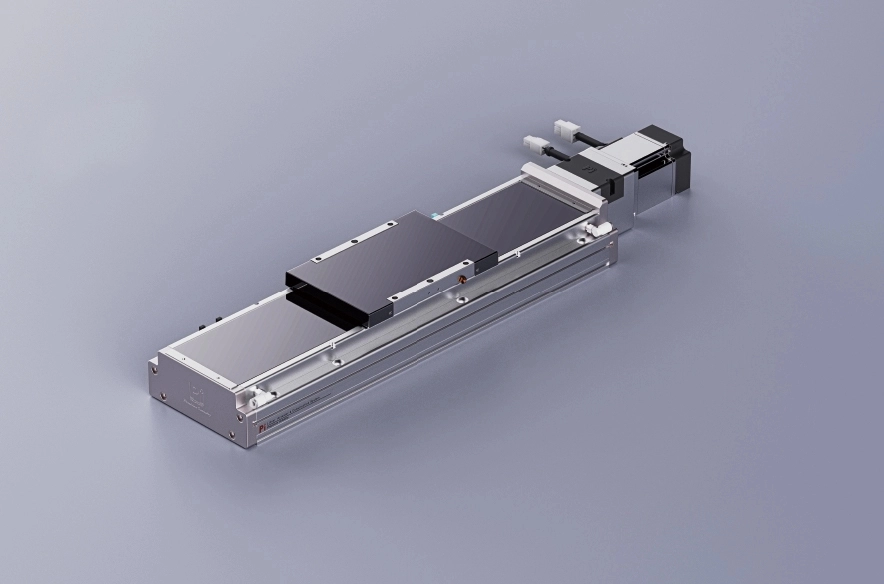

Repeatability:±0.005/0.01mmHorizontal Load:150kgVertical Load:55kgMaximum Speed:2000mm/sTravel Range:100-1500mm

Current location:Home > Company > News > Latest news > Top 5 Features to Look for in a Precision Positioning Slide Table

Current location:Home > Company > News > Latest news > Top 5 Features to Look for in a Precision Positioning Slide Table Date: Jan 28 2026

When it comes to precise movement and accurate positioning in various industrial, scientific, and engineering applications, a precision positioning slide table is an essential piece of equipment. Whether you're involved in automation, robotics, optics, or semiconductor manufacturing, choosing the right slide table can significantly improve the efficiency and precision of your processes. Here’s a breakdown of the top five features to look for when selecting a precision positioning slide table:

At the heart of any precision positioning slide table is its ability to deliver highly accurate movements and repeatable positioning. The key factor here is the linear accuracy, which determines how closely the slide table can match the desired position. Look for a slide table that offers sub-micron or micron-level accuracy. This feature is crucial for applications that require fine movements such as laser alignment, optical experiments, or automated assembly tasks. Additionally, repeatability is just as important—ensuring that the slide table returns to the exact position every time is vital for maintaining consistent results in long-term operations.

No matter how precise the slide table is, its performance can be compromised if it can’t support the necessary load without sagging or wobbling. The stability of the table, especially under heavy loads or continuous use, is essential. Choose a slide table with a robust frame design that can handle the weight of your equipment or components without causing deformation. Stability also involves the materials used in the table's construction—aluminum, stainless steel, and carbon fiber are common materials known for their strength and minimal thermal expansion. The load capacity rating will give you an idea of the maximum weight the slide table can carry while maintaining its precision.

The movement of a precision positioning slide table should be smooth, fluid, and free from jerks or stutters, as this ensures high precision. The friction within the system should be minimal, which reduces wear and tear on the internal components, prolonging the lifespan of the table. This is typically achieved through the use of precision ball bearings or air bearings, which provide smooth, controlled motion. Look for a slide table with low friction coefficients and good lubrication options to reduce resistance during movements. The smoother the motion, the better the accuracy and reliability over time.

A great precision positioning slide table should offer a variety of actuation methods to suit different applications. Depending on the requirements of your project, you may need a table with manual, electric, or pneumatic actuation. Electric motors are ideal for automation setups, offering programmable control and high precision. Manual operation may be preferred for simpler applications that don’t require continuous movement but still need precision. Furthermore, some advanced models feature closed-loop systems with feedback control, allowing real-time adjustments and better accuracy under varying load conditions.

In many cases, space constraints are a consideration. A compact design allows the slide table to fit into smaller, more confined spaces without sacrificing performance. However, even within a compact form, the slide table should not compromise on its precision or load capacity. Look for models that offer customization options for specific needs—whether it’s adding a larger stroke length, modifying the table’s width, or incorporating specific mounting points for your equipment. Customization can make a significant difference in ensuring that the slide table perfectly fits the environment and application it’s intended for.

Selecting the right precision positioning slide table for your application can be the difference between smooth, efficient operation and costly errors. By focusing on precision and repeatability, stability and load capacity, smooth movement and low friction, flexibility in actuation, and compact design with customization options, you can ensure that you are choosing a slide table that not only meets but exceeds the demands of your task.

When evaluating slide tables, always consider the unique needs of your application. With the right features in mind, you'll be able to make a well-informed decision, ultimately optimizing performance and enhancing productivity. Whether you're using the slide table in research, manufacturing, or automation, these features will help you achieve greater accuracy and reliability in your work.