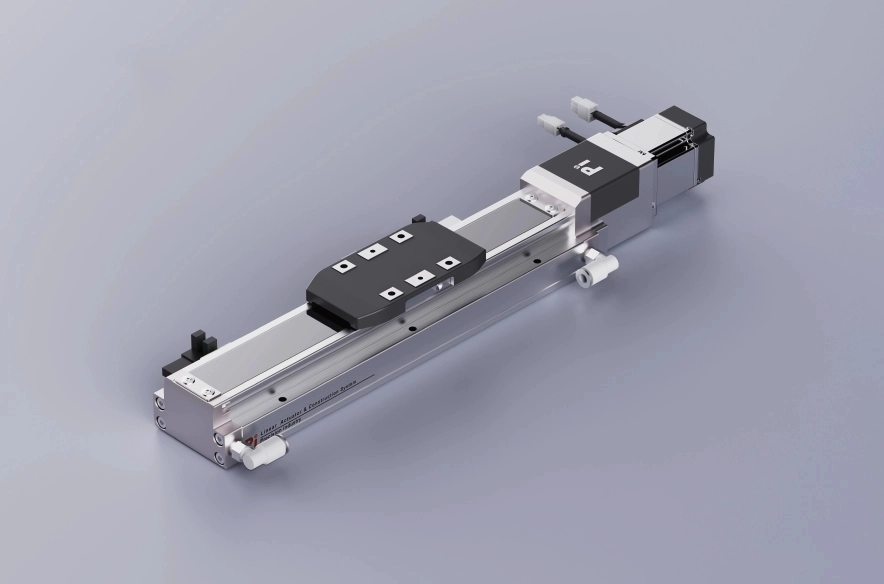

Repeatability:±0.005/0.01mmHorizontal Load:150kgVertical Load:55kgMaximum Speed:2000mm/sTravel Range:100-1500mm

Current location:Home > Company > News > Latest news > A Comprehensive Guide to Buying Precision Positioning Slide Tables

Current location:Home > Company > News > Latest news > A Comprehensive Guide to Buying Precision Positioning Slide Tables Date: Jan 28 2026

When you’re in the market for a precision positioning slide table, whether for robotics, automation, optics, or any other industry requiring exact movements, the options can be overwhelming. Selecting the right slide table isn’t just about price—it's about getting the right balance of accuracy, durability, and flexibility to meet the demands of your specific application. This guide will take you through the most important factors to consider when purchasing a precision positioning slide table.

The first step in choosing a precision positioning slide table is understanding your precision requirements. Precision is often measured in microns or even sub-microns, depending on the application. For instance, in industries like semiconductor manufacturing or optical alignment, you may need slide tables that offer high-precision movements, often with accuracy ratings of 0.5 micron or better.

Ask yourself these questions:

How precise do the movements need to be?

What level of accuracy is required for your application?

If precision is paramount, look for tables with low backlash and high repeatability. These characteristics will ensure that the table can move to an exact position and return to it consistently.

Every precision slide table comes with a maximum load capacity. The load capacity is determined by the strength and rigidity of the table’s construction, and it’s crucial to ensure the slide table can handle the weight of your components without compromising performance.

For example, industrial automation systems often require slide tables with higher load capacities because they are used for larger or heavier parts. On the other hand, applications in microsystems may need slide tables with a lower load but extremely high precision.

Here are key things to keep in mind:

Weight of the components: Will the slide table need to carry heavy equipment?

Dynamic load vs. static load: Does the slide table need to support the weight while in motion or just when stationary?

The travel range refers to the maximum distance the table can move in a single operation. Depending on your application, this could range from just a few millimeters (for fine adjustments in optical systems) to several meters (for heavy-duty operations in automated assembly lines).

When selecting a table, consider the following:

Do you need a long stroke length for your application, or will a shorter stroke suffice?

Is the stroke length adjustable, or does the table come with fixed travel distances?

Ensure the slide table can cover the necessary distance without limiting your process.

Precision slide tables can be actuated using various mechanisms, each suited to different types of applications:

Manual Actuation: For low-volume or less complex applications, a manual positioning system may be enough. Manual slide tables are ideal for applications requiring occasional adjustments but do not require continuous, automated motion.

Motorized Actuation: For automated, high-speed, or repeatable movements, a motorized slide table is the best choice. This can be driven by stepper motors, DC motors, or servo motors. Choose motorized systems if you need automated control, precise movement, or integration with a larger robotic or control system.

Pneumatic or Hydraulic Actuation: In some specialized applications, such as material handling or heavy-duty machining, you may need pneumatic or hydraulic actuators for smooth, high-force movements.

Make sure the actuation system fits your application’s speed and control requirements.

A precision slide table must be stable and rigid, especially when supporting heavy loads or operating at high speeds. If the table flexes or wobbles under pressure, it can lead to inaccurate positioning and damage to sensitive components.

Look for these characteristics to ensure stability:

Material selection: Tables made from stainless steel or anodized aluminum typically offer good rigidity while remaining lightweight.

Design: Look for a rigid frame design that minimizes flexing under load.

Support mechanism: High-quality slide tables often feature precision bearings or guide rails that prevent lateral movement and improve stability.

A stable slide table will reduce errors and improve the overall performance of your system.

No matter how precise or accurate a slide table is, it’s important to choose one that is low-maintenance and durable. Some tables come with sealed bearings, self-lubricating parts, and corrosion-resistant coatings that reduce the need for frequent maintenance. Others may require regular lubrication or upkeep to maintain their precision.

Here’s what to look for:

Self-lubricating: Opt for tables that require minimal maintenance.

Corrosion-resistant materials: Especially if the slide table is used in harsh environments like laboratories, clean rooms, or outdoor settings.

Ease of maintenance: Some slide tables are designed for easy disassembly or feature maintenance ports to facilitate cleaning and part replacement.

Investing in a durable, easy-to-maintain slide table will help you avoid downtime and unnecessary repairs.

While many precision positioning slide tables come with standard features, your specific application may require additional customization. Some manufacturers offer a range of customization options, including:

Modified stroke lengths

Custom mounting fixtures

Alternative actuators

Special coatings for high-temperature or high-corrosion environments

Consider whether you need any custom features, and ensure that the manufacturer can accommodate these needs. Customized slide tables can help you achieve the exact performance required for your application.

Finally, it’s important to assess how well the slide table integrates with other equipment in your workflow. Some slide tables come with built-in controllers, position feedback systems, and mounting options that make it easier to integrate with robotic arms, automation systems, or custom test rigs.

Check for:

Communication protocols (such as RS-232, Ethernet, or Modbus) if you need to connect to a larger control system.

Compatibility with other automation systems: For example, if you’re using a robotic arm or CNC machine, the slide table must integrate smoothly with those systems.

Purchasing a precision positioning slide table isn’t a one-size-fits-all decision. The best choice depends on factors such as precision requirements, load capacity, travel range, actuation system, and stability. By understanding the demands of your specific application and evaluating your options carefully, you can select the right slide table that will improve your system’s accuracy, reliability, and overall performance.

Keep these factors in mind when you start shopping for a slide table, and you’ll be well on your way to making an informed decision that enhances your operational efficiency and meets the needs of your application. Whether you’re handling delicate equipment or large, heavy components, the right precision positioning slide table will ensure smooth and accurate movement, helping you achieve your goals more effectively.